Automation is not a new concept. At the core of the Industrial Revolution of the 1760s were new manufacturing technologies that allowed for the automation of production processes. We are currently experiencing another such revolution, but it’s different this time.

We live in an era of explosive technological advancement enabling humanity to do what was once unfathomable in the most hardcore of science fiction circles. Robotics, biotech, artificial intelligence, deep learning, 3D printing, and many other areas of research have unlocked incredible opportunities.

The capability and result of automation with these new technologies are broad and deep.

Positive Effects of Automation

The positive effects of automation are limited only by the human imagination. With the continued advancement of artificial intelligence and deep learning, machines can learn to do all kinds of tasks including, but not limited to: manufacturing advanced electronics, constructing a building, navigating a vehicle, or identifying possible tumors or bone fractures; and they can do it better than their human counterparts.

Production

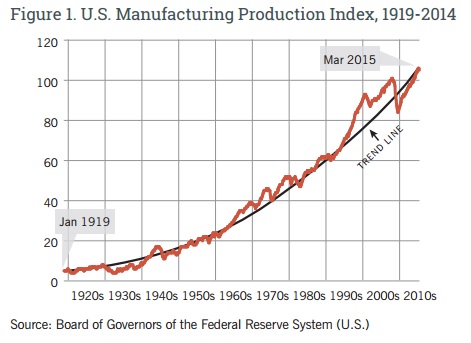

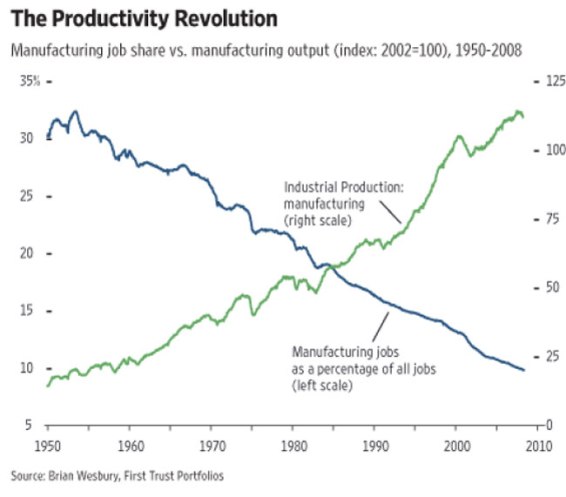

Manufacturing is the poster child of automation. Automation has revolutionized manufacturing processes around the globe. The United States, which experienced a decrease of 5 million manufacturing jobs since 2000, saw consistent growth in manufacturing output5,6:

“From 2006 to 2013, manufacturing grew by 17.6%, or at roughly 2.2% per year”5

Automation decreases the cost of production and results in higher quality goods. An example: the Changying Precision Technology Company, a Chinese company that produces mobile phones, recently replaced 90% of it’s workers with robots and realized a 250% gain in output while reducing product defects by 80%7.

Travel

Self-driving cars, in live tests, have proven themselves capable of driving safely. In fact, Google’s self driving cars, which have logged more than 1.7 million miles, only experienced 11 accidents8. The kicker: None of the accidents were by fault of the self-driving vehicle.

Here are some estimated annual results of replacing just 20% of human-driven vehicles with self-driving vehicles9:

- 21,700 fewer deaths

- 4,220,000 fewer crashes

- $109.7 billion in economic savings

- 2.8 billion hours saved through reduction in travel times

- 724 million gallons of gasoline saved

Self-driving cars regulate traffic better than human drivers by maintaining safe speeds and distances. Better yet, self-driving cars are not susceptible to distractions leading to accidents. Self-driving could even enable those who are currently unable to drive to re-establish their independence in areas that are lacking public transportation.

Click here for a much more in-depth report on the economic effects of automated vehicles.

Improved Healthcare

Artificial intelligence and deep learning in the development of health information systems has resulted in systems that have the ability to classify malignant tumors, sort through images to identify possible malignant lung nodules, and detect bone fractures; and that’s just Enlitic’s software1.

Enlitic isn’t just good software, it’s 50% better than seasoned human experts at classifying malignant tumors and has a false-negative rate, while humans came in at 7%1.

Health information systems, electronic health records, and process automation also allow for lightning-fast decision making and instant access to vital information that can save a patient’s life; all while slashing overhead costs.

The same systems can integrate billing, pharmaceutical, long-term care, preventative care, and any number of other sub-packages allowing for streamlined processes.

On a larger scale, the ability for these systems to collect and transfer data for aggregation allows for analysis on a nationwide scale to catch outbreaks and track other social health trends, allowing public policy and response to rapidly resolve issues or make adjustments where necessary to improve healthcare.

Inexpensive Goods and Services

Reductions in labor expenses as well as greater efficiency in the manufacturing of products and information services should result in lower costs to consumers. Lower costs allow consumers to make more use of their income to either purchase more goods and services, or to save and invest extra income.

Not to forget that 3D printing technology mentioned earlier. In the future, with your “Everything-In-One” 3D printer, instead of going to the hardware store to buy a new hammer all you’ll need to do is download the specs and your printer will whip one up for you. Maybe you need a part to fix an older model appliance. No need to order an aftermarket part from China and wait weeks for it to arrive. Print one out.

NASA has been 3D printing objects on the International Space Station. In the future, instead of needing to wait for supplies to arrive on the next shuttle, the station will be able to print out what they need on the fly12.

Negative Aspects of Automation

Job loss

47% of American workers are at high risk of potential automation. Highest risk workers include transport and logistics, office support, and sales and services1.

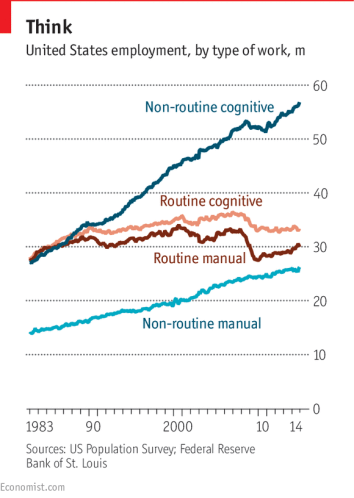

As routine cognitive and routine manual jobs are automated, a two tier system develops. High paying non-routine cognitive and low paying non-routine manual jobs increase in number, while median wage jobs stagnate or disappear entirely.

Past eras of automation, the industrial revolution for example, didn’t necessarily result in mass unemployment so much as allow for greater production capabilities resulting in a shift of the workforce to fill new, less labor-intensive roles.

The difference with automation today is the combination of advanced robotics, artificial intelligence, and deep learning technologies. This gives machines the capability to completely replace human beings in many capacities in the broad market, rather than in an industry or two2. Rather than using machines to augment the workforce they will begin to replace it entirely.

Manufacturing jobs are just the beginning4:

Disproportionate Income Distribution

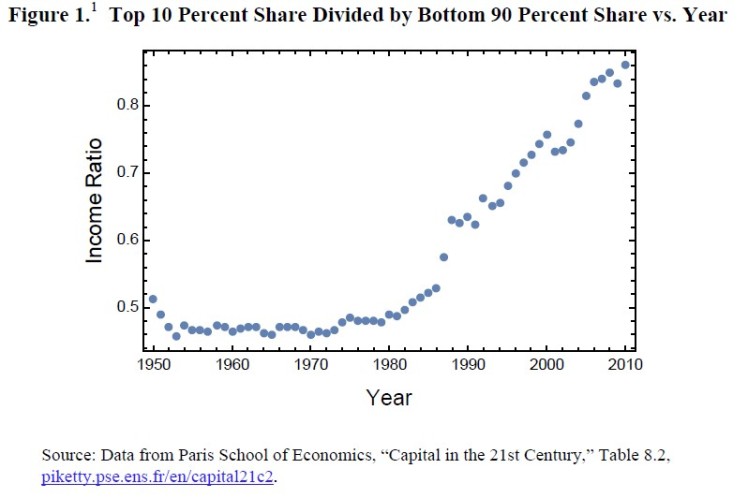

Those whose jobs are much harder to automate end up in one of two categories. The first include jobs that are highly cognitive in nature, and high paying. The second includes low paying manual labor jobs. This increased inequality in the distribution of labor and wages reduces economic opportunity and socioeconomic mobility, but that’s not the worst part.

The automation of jobs requires capital expenditures up front and long term maintenance costs. Companies can often use these expenses to reduce tax burdens and ultimately increase profit margins. Once complete, companies are able to drastically reduce costs by laying off the workers whose jobs have been automated. Fewer employees means fewer salaries, taxes, healthcare expenses, and other benefits.

Less expense to a company might result in a drop in price for their goods or services, but it is much more likely results in a greater portion of profits returned to it’s owners. Meanwhile, the workers who have been laid off must now compete against other workers who have been laid off for the few remaining jobs. In the current system, if a worker is lacking particular skills for a job they often have to incur personal debt to obtain the required skills to obtain a new job.

The net result is more debt for workers and more profit for the already wealthy. There is proof to support this claim. As automation increased exponentially in recent decades, much greater portions of income were distributed to the wealthiest 10%3:

“In 1970, the top 10% of the population earned about 32 percent of labor income; by 2012 the share of the top 10 percent has increased to 47 percent.”3

Decentralization of Production Processes

3D printing technology is relatively new, but developing rapidly. As it is improved and additional materials are available to these new printers, consumers will be less reliant on mass production techniques to fulfill their needs.

Items that are less complicated to produce will experience dramatic declines in demand as consumers are able to produce their own as needed. This will disrupt traditional production paradigms.

Conclusion

Automation gives us, as a society, an opportunity to refocus the efforts of our workforce on more creative and personal ventures. Greater efficiency allows us to consume fewer resources, waste less time on tedious tasks and travel, and pay less for goods and services.

However, to get there we must radically rethink social and economic structures. Rapidly accelerating income and wealth inequality, if not addressed, will cause an economic collapse as fewer people are able to afford goods and services. We need to prepare for the possibility that large portions of the population could be displaced rapidly. There are some steps we can take now to prepare ourselves for this shift:

Allocate additional resources to skill development and re-education of the workforce to aide employment transitions.

Implement a Universal Basic Income to replace welfare programs and guarantee a minimum level of income for all American citizens.

Encourage companies to offer equity compensation to all employees.

References

1 The Economist. 2016. Automation and anxiety.

2 Pacific Standard. 2015. The Future of Work: Automation’s Effect on Jobs – This Time Is Different.

3 Brito, Curl. 2015. Turing Robots: Income Inequality and Social Mobility.

4 SupplyChainDigest. 2008. Supply Chain Graphic of the Week – Automation, Not Offshoring, Real Source of Manufacturing Job Loss.

5 Lehmacher. 2016. Don’t Blame China For Taking U.S. Jobs.

6 Hicks, Devaraj. 2015. Manufacturing in America.

7 Andrei. 2017. Chinese factory replaces 90% of human workers with robots. Production rises by 250%, defects drop by 80%.

8 Govers III. 2015. Google reveals lessons learned (and accident count) from self-driving car program.

9 Johnson. 2014. The Pros and Cons of Driverless Cars.

10 Clements, Kockelman. 2017. Economic Effects of Automated Vehicles.

11 Ayehu. How IT Process Automation Can Revolutionize The Healthcare Industry.

12 National Aeronautics and Space Administration. 2014. Space Station 3-D Printer Builds Ratchet Wrench To Complete First Phase Of Operations.